Capabilities

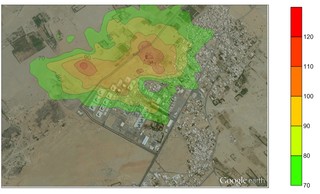

AWN Consulting has extensive capabilities in the application of a range of state of the science air dispersion models to assess the impact of major industrial facilities such as power stations, incinerators, pharmaceutical plants and waste facilities.

USEPA AERMOD and CALPUFF air dispersion models can both be applied depending on the complexity of the assessment. In Ireland, due to proximity to the coast and mountainous terrain, CALPUFF may have some important advantages over steady-state Gaussian models such as AERMOD in areas of complex terrain. Firstly, AERMOD, being a steady state straight line plume model cannot respond to the terrain-induced spatial variability in wind fields. Secondly, as AERMOD is based on a single-station wind observation, the wind fields do not vary spatially within the modelling domain. Thirdly, AERMOD cannot treat calm conditions and does not calculate concentrations during these hours. Because of these limitations, CALPUFF would be expected to more accurately reflect the meteorological and dispersion characteristics of the modelling domain in areas where it is significantly influenced by terrain and thus lead to more accurate ambient air concentrations.

- Stack height determination of industrial air emission points;

- Assessment of industrial facilities compliance with ambient air quality legislation;

- Determination of the appropriate abatement efficiencies for a range of abatement equipment;

- Assessment of the influence of new buildings in terms of building downwash and consequences for ambient concentration of pollutants;

- Determination of critical levels and loads of ammonia, N (nitrophication, eutrophication) and acidification in SACs / NHAs / SPAs;

- Determination of the maximum emission envelope for a facility and optimisation of emissions across a facility;

- Land use planning and risk assessment of proposals for developments in the vicinity of an industrial facility;

- Human health risk assessments including air dispersion modelling and uptake risk assessments for facilities such as thermal treatment operations;

- Impact of new processes / process change in terms of air emissions.